Silicon Wafer Custom Double Side Polished Si Substrate 2‘ 3’ 4‘ 6’

Silicon Wafer Custom Double Side Polished Sic Wafer Substrate 2' 3' 4' 6' 1. what is silicon wafers and it's application

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | FW-CRYSTAL |

| Manufacturing Technology | Optoelectronic Semiconductor |

| Material | Compound Semiconductor |

| Type | Intrinsic Semiconductor |

| Package | SMD |

| Signal Processing | Analog Digital Composite and Function |

| Application | LED |

| Growth Method | CZ and Fz |

| Orientation | 111 or 100 |

| Resistivity | 0.0005 to 150 |

| Surface | Double Side Polished or Single Side Polished |

| Dopant | N Type and P Type |

| Particles | <30 at 0.3um |

| Bow | < 30 Um |

| Ttv | <15 Um |

| Transport Package | Box |

| Origin | Jiaozuo Henan |

| Production Capacity | 100, 000PCS/Month |

Product Description

Silicon Wafer Custom Double Side Polished Sic Wafer Substrate 2' 3' 4' 6'

1. what is silicon wafers and it's application:

A silicon wafer is a material essential for manufacturing semiconductors, which are found in all kinds of electronic devices that enrich our lives.

Silicon wafer is the most common material and widely used for a varity of high-tech industries, including integrated circuits, detector or sensor device, MEMS fabrication, opto-electronic components, and solar cells.

Silicon wafer is a very thin round disk cut from high-purity silicon. A round silicon ingot is sliced to thicknesses of approximately 1mm. The surfaces of the resulting disk are polished carefully, then it is cleaned, resulting in the completed wafer. Silicon wafers are made from high-purity silicon, and are the material of semiconductor devices. These wafers can also be fabricated with a SEMI notch or one or two SEMI flats.

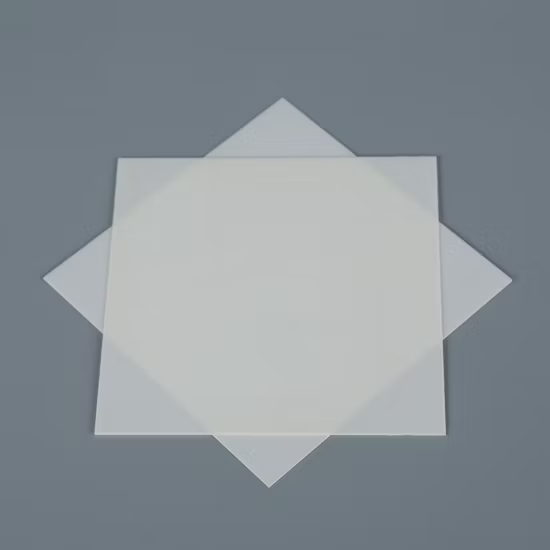

Product picture

2. Manufacturing a Silicon Wafer

Growing a silicon ingot can take anywhere from one week to one month, depending on many factors, including size, quality and the specification. More than 75% of all single crystal silicon wafers grow via the Czochralski (CZ) method.

3.Equipment we use

| Grow method | CZ or FZ |

| Diameter | 1 to 8 inch |

| Finish | As cut, lapped, etched, SSP, DSP |

| Orientation | (100) (111) (110) |

| Type | N or P |

| Resistivity | CZ: From 0.0005 to 150 Ωcm FZ: Up to 10 kΩcm |

5.FAQ:

Q: What's the way of shipping and cost?

A:(1) We accept DHL, Fedex, TNT, UPS, EMS etc.

(2) If you have your own express account, it's great.If not,we could help you ship them.

Q: How to pay?

A: T/T, Paypal, etc

Q: What's your MOQ?

A: (1) For inventory, the MOQ is 5pcs.

(2) For customized products, the MOQ is 10pcs-25pcs.

Q: What's the delivery time?

A: (1) For the standard products

For inventory: the delivery is 5 workdays after you place the order.

For customized products: the delivery is 2 or 3 weeks after you place the order.

(2) For the special-shaped products, the delivery is 4 or 6 workweeks after you place the order.

Q: Do you have standard products?

A: Our standard products in stock.

Q: Can I customize the products based on my need?

A: Yes, we can customize the material, specifications and optical coating for your optical components based on your needs.